What is the Difference between FE 500 & FE 500D TMT Rebar?

TMT Rebar is the backbone for all type of construction.

There cannot be any compromise with the quality of TMT Rebar. While constructing it is mandatory to choose only the best quality TMT Rebar that has withstand the load during natural calamities such as an earthquake, flood or from fire. Poor quality TMT Rebar contains high level of unknown material that are harmful for structures.

TMT stands for ‘Thermo Mechanical Treatment’ that is also known as metallurgical process. These TMT Bars are manufactured under the IS (Indian Standards) Standards.

In today’s market FE 500 & FE 500D TMT Bars are most used for all civil & retail construction purposes.

Standard Grades of TMT Bars as per IS are:

Fe 415 | Fe 415D | Fe 500 | Fe 500D | Fe 550 | Fe 550D | Fe 600

In any RCC construction, TMT Re-bar and cement are the two most important components. The life span and safety of these types of structures entirely depends on the properties of the Re-bar and Cement. Designers / Engineers should accept TMT Re-bars, only after proper testing and verification of the same irrespective of the name of the manufacturer.

What are the Special Features of TMT Steel Bar?

- Best quality TMT Bars comes with perfect balance of Strength & Flexibility for low carbon content in it.

- TMT Bars go through Bend & Re-Bend test because they are relatively high strength steels, and the ribs on the bar surface act as stress concentrators.

- Higher yield strength, Ultimate tensile strength and higher percentage elongation when compared to cold twisted bars (CTD) of same grade.

- Highly Weldable that makes it usable for all purposes

- Highly Corrosion Resistant & Earthquake Resistant

- Using Fe 500D TMT Rebar can save 1.70 kg. Per metric ton.

- TMT Bars contain lesser amount of Sulphur that makes the structures Fire Resistant

- Metallurgical Process called as “Thermo Mechanical Treatment” is about dephosphorize the steel in the ladle and desulphurize the steel in Ladle Refining Furnace and now steel is at par with Primary steel producers.

Properties of 500D TMT Bar

It is important to follow the IS Standards so that the TMT Bar becomes Strong, Flexible and Fire Resistant. TMT Bars can exchange sudden loads during an earthquake/flood etc for its high ductility.

Chemical Structure in TMT Bar determines the best elongation. In Grade Fe 500& Fe 500D contain the lowest amount of Sulphur & Phosphorus that makes these grades highly acceptable for all construction purposes.

Higher percentage of Sulphur makes the steel prone to Fire & over usage of phosphorus cause fatigue to the steel bar.

| Elements | #Percent, Maximum | |

| Fe 500D | Shyam Fe 500D TMT Rebar | |

| Carbon | 0.25 | 0.22 |

| Phophorus & Sulphur | 0.40 | 0.035 |

| Phosphorus + Sulphur | 0.075 | 0.065 |

| CE | 0.42 | 0.350 |

| Nitrogen | 120 | 100 |

All TMT Bars being tested in UTM (Universal Testing Machine), that is used to test the tensile strength and compressive properties of the material.

Determination of 0.2% Proof Stress / Ultimate Tensile Strength / Elongation / TMT Re-bar As Per IS: 1786/2008.

Ultimate Tensile Strength = Ultimate Tensile Load (KN) / Cross Sectional Area (mm2)

Minimum Yield Stress and Tensile Strength for different grade of TMT Re-bars are mentioned below as per IS-1786/2008

| Property | Grade | ||||||

| Yield Stress/0.2% Proof Stress. (Minimum) N/mm2 | Fe 415 | Fe 415D | Fe 500 | Fe 500D | Fe 550 | Fe 550D | Fe 600 |

| 415 | 415 | 500 | 500 | 550 | 550 | 600 | |

| Tensile Strength, Minimum | 10% more than 0.2% PS, but not less than 485.0 N/mm2 | 12% more than 0.2% PS, but not less than 500.0 N/mm2 | 8% more than 0.2% PS, but not less than 545.0 N/mm2 | 10% more than 0.2% PS, but not less than 565.0 N/mm2 | 6% more than 0.2% PS, but not less than 585.0 N/mm2 | 8% more than 0.2% PS, but not less than 600.0 N/mm2 | 6% more than 0.2% PS, but not less than 660.0 N/mm2 |

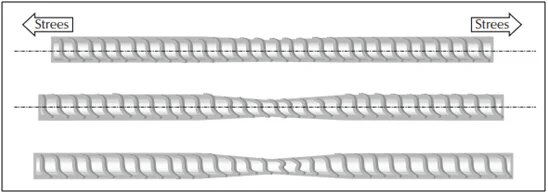

Different phases of the test piece under tensile test

Standard minimum elongation percentage on gauge length for different grade of TMT Re-bars are mentioned below as per IS-1786/ 2008

| Property | Grade | ||||||

| Elongation percentage (minimum) | Fe 415 | Fe 415D | Fe 500 | Fe 500D | Fe 550 | Fe 550D | Fe 600 |

| 14.5% | 18.0% | 12.0% | 16.0% | 10.0% | 14.5% | 10.0% | |

Why FE 500D is most preferred TMT Bar?

“Fe” denotes iron in TMT Bar & “D” stand as Elongation. In Fe 500 & FE 500D TMT Bar “500” implies the minimum yield stress in MPa. FE 500D has higher percentage of elongation than any other Grade of TMT Bar.

| FE 500 | FE 500D | |

| 0.2% Proof Stress (min N/mm2) | 540 | 560 |

| Ultimate Tensile Strength (min N/mm2) | 640 MPa | 660 MPa |

| Elongation (In Percent) | 18 | 20 |

| Carbon (Max) | 0.25% | 0.22% |

| Phosphorous & Sulphur (max) | 0.050 | 0.035 |

The best TMT Bar should have the quality to

- Absorb extra energy during an earthquake

- Protect the building from Fire

- Corrosion Resistance

Also the points that we discussed in this article points that the FE 500D TMT Rebar is the best for all construction purposes whether it is civil construction or retail purpose. Its extreme ductility, weldability, bendability is not parallel with any other grade of TMT Rebar.