What is Bar Bending Schedule (BBS) of TMT Bar?

Building home requires several factors to be taken under consideration to get the best result. Before you start the construction of your home you need to have the perfect planning, accurate estimation and best quality building materials.

In construction TMT Bar is one of the prime material that makes your home

- Fire Resistant

- Earthquake Resistant

Thus, it is important to choose the best quality TMT Bar that has the perfect balance of strength & flexibility and makes your home everlasting. TMT Bars are widely used for its ductility and bendability. TMT Bar is an advance technology that used in all type of construction. The Thermo Mechanical Treatment results strong outer martensite layer in outer side that results the tensile strength to it and soft ferrite-pearlite inner core makes it highly ductile. TMT Bars are well known for its bendability.

Here we are going to discuss about the Bar Bending Schedule (BBS) that will help to simplify the steel bar estimation for construction and advantage of it.

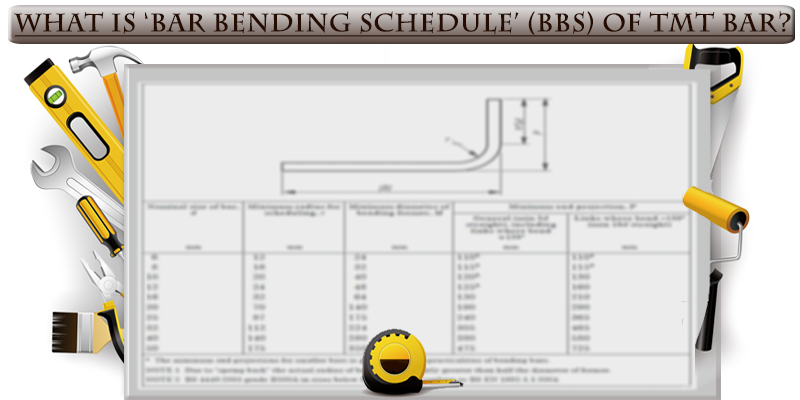

Bar Bending Schedule or Schedule of Bar is performed depending upon the reinforced concrete work item. Bar bending agenda summarizes all of the wanted particulars of bars – diameter, shape of bending, length of every bent and straight portions, angles of bending, overall length of every bar, and number of each type of bar. This facts is a exquisite assist in preparing an estimate of quantities.

What is Bar Bending Schedule?

Calculation of the total quantity of TMT Steel Bar required for building construction is termed as Bar Bending Schedule. Steel Bar reinforce in concrete structure therefore the construction structure can withstand during the tension. How much TMT Bar required constructing your home? What type of steel bar is best for construction? How much TMT Bar required in RCC? These all queries can be served during Bar Bending Schedule (BBS).

Modification in Bar Bending Schedules

Construction industry rapidly changed in last few decades. Previously three to four-storey building were considered to be high rise but with the rapid growth in construction industry we could see 100+ storey buildings very often.

According to the old construction method using four steel bars in column was standard but now we are using 15+ steel bars in column based on load analysis. Rise in world population demanded more spaces in small area.

Bar Bending Schedule (BBS)

It is important to learn the basics before dealing with BBS

| Particular | Result |

| Standard Length of TMT Steel Bar | 12M or 40’ |

| Weight of bar for length = 1m | (Dia of Bar)*2/162 |

| Steel Density | 7850 Kg/m3 |

Important points to be noted for Bar Bending Schedule

- TMT Steel Bars should be kept together in a group that can be identified for each structural unit and list should be well distributed for each floor

- Bars should be in numeric order numbers

- Each bar in bundle should be labeled properly with length, size and shape of the bar

- In bar bending cutting schedule cutting length and bending length calculation should be done separately.

Important Usage of Bar Bending Schedule

- Bar Bending Schedule (BBS) helps to determine the quantity of steel required in construction of your house. This helps to get the accurate estimation of steel

- Once the calculation of cutting and bending is done it reduces the wastage of steel and it becomes economic

- Once you get the reinforcement drawings, cutting and bending can be done at warehouse before transportation. It increases the speed of construction and the transportation cost also reduces.

- Before placing the concrete if the bending and cutting length of TMT Steel bars are measured it becomes easier for site engineers.

To know more about home building be in touch with our experts Expert Advice for House Construction