Different Tests to ensure the Best Quality TMT Bars

The global demands for TMT Bars (Thermo Mechanically Treated Bars) are rising day by day. To get the best enforced structures TMT Bar is the best alternative. There are so many brands in market but need to select the best quality TMT Bar that makes your home long lasting.

In order to ensure the quality of TMT Bar there are certain tests by which you can ensue it. TMT Bars comes in different grades such as Fe 415, Fe 500, Fe 550, Fe 600, the numbers denotes the yield strength.

Which Grade of TMT Bar is best for Construction?

TMT Bars needs to have the perfect combination between strength & flexibility. As per IS Standards Fe 500d Grade steel reinforcement bars has the perfect combination of strength & flexibility. It is mostly recommended for all type of construction purposes.

However to determine the strength & elongation certain number of tests are performed to ensure its quality. The tests are as follows

- Tensile Test

- Yield Stress Test

- Bend & Rebend Test

- Chemical Analysis Test

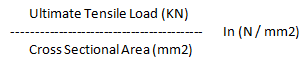

What is Tensile Test in TMT Bar?

To measure the strength of reinforcement bars Universal Testing Machine (UTM) is used. Upto 32 mm capacity of TMT Bars can be tested without machine as per IS 1786 and above which need to be tested with it.

Calculation

Determine the cross section area of TMT Re-bar.

- Weight of the Re-bar of 500mm = X mm (b) Length of the Re-bar (Area in mm2 = Weight / Length x 0.00785)

IS: 1786 / 2008 (Clause 6.3.1)

Ultimate Tensile Strength =

What is Yield Stress Test in TMT Bar?

A Material can take stress upto which level? At which level it will begin to deform plastically? These are factors can be determined during Yield Stress Test/0.2% Proof Stress. Until the material reaches to the yield point it will deform elastically and return to its original shape when the applied stress is removed.

The standard procedure is to project a line parallel to the initial elastic region starting at 0.002 strains. The 0.002 strain point is often referred to as the 0.2% offset strain point.

The behavior of the material can be broadly classified into two categories, brittle and ductile. Steel and aluminum usually fail in the class of ductile materials. Glass and cast iron fall in the class of brittle materials. The two categories can be distinguished by comparing the stress-strain curve.

What is Bend & Rebend Test in TMT Bar?

In many cases you can find that TMT Bars are getting deformed. It happens because of wrong handling of the materials. So, one must be careful while bending and re-bending the TMT at construction sites. When bending or re-bending is done at a construction site, it is to be ensured that the bend radii are not formed below the prescribed minimum sizes in the relevant standards. Incorrect bending can severely affect the performance of steel reinforcement in service.

Important Points to be noted while bending TMT Bars

- Bending should be done gradually & slowly. It needs not to be vibrated while performing it.

- Minimum bend diameters have been established for different bar sizes.

- Bending with pipe of hammer should be strictly prohibited

- TMT Bars should not have dirt/mud in it.

It is essential to select TMT Bars that are manufactured at ISP’s where advanced quenching technologies are used while manufactured. Better tensile strength & elongation comes during the quenching. So BIS Licenses, World Class Quenching Technology such as Thermex these are the main criteria to select the best quality TMT Bars.

Bend Test

The bend test consists of bending a test sample of TMT Re-bar through plastic deformation by applying a load against a suitable mandrel until a specified angle (180 degree) of bend is reached. Depending on the requirements of the material standard such as IS 1786/2008; it should be parallel at a specified distance, an insert is used to control this distance. Test is usually carried out at room temperature and the bending arrangement with two supports (S1 & S2) and a Mandrel (M) has been shown below.

The length (L1) of the test piece depends on the diameter (Φ) of the Re-bar and the Test equipment used. If the distance (L2) between the supports is not specified, then L2 can be calculated as follows:

L2 = Md + 3Φ [Md = Mandrel Diameter]

The mandrel diameter used for different grades of TMT Re-bar for Bend test are given below as per IS 1786-2008

| Nominal Size | Fe 415/415D | Fe 500/500D | Fe 550/550D | Fe 600 |

| Up to & Including 10 mm | 5Φ | 4Φ | 7Φ | 6Φ |

| Over 10 mm | 4Φ/3Φ | 5Φ/4Φ | 6Φ/5Φ | 6Φ |

* Φ is the diameter in mm of the test sample

* : The sample shall be considered to have passed the test if there is no rupture or crack visible at the bend (tension zone) portion to a person of normal vision.

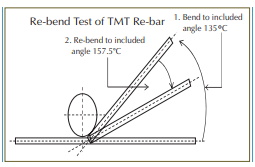

Re Bend Test

This test is designed to measure the effect of strain ageing on the steel. Strain ageing is an embrittlement effect, which occurs after cold deformation, by the diffusion of nitrogen in the steel. The risk of fracture on bending is increased as the temperature is decreased, because these steels have decreasing toughness at lower temperatures. Hence, temperature parameters should be followed as per code for correct result.

The Re-bend test consists of bending a sample of TMT Re-bar through plastic deformation by applying a load against a suitable mandrel to an included angle of 135 degree. The bend sample should be aged by keeping in boiling water (100 degree C) for 30 minutes and then allowed to cool. The sample should be bent back to have an included angle of 157.5 degree. Test is usually carried out at room temperature. The mandrel diameter used for different grades of TMT Re-bar is given below.

The sample which has been used for bend test is not to be used for Re-bend test.

While applying load on the sample bar it is important to ensure that the load is uniform, smooth and vertically downwards. Impulse load should be avoided.

The specified mandrel diameter used for different grades of TMT Re-bar for Re-bend test are given below as per IS 1786-2008.

| Nominal Size | Fe 415 & Fe 500 | Fe 415D & Fe 500D | Fe 550 & Fe 600 | Fe 550D |

| Up to & Including 10 mm | 5Φ | 4Φ | 7Φ | 6Φ |

| Over 10 mm | 7Φ | 6Φ | 8Φ | 7Φ |

* Where Φ is the diameter in mm of the test sample.

* The sample shall be considered to have passed the test if there is no rupture or crack visible at the bend (tension zone) portion to a person of normal vision.

What is Chemical Analysis Test in TMT Bar?

Cross section wise 50mm/60mm length sample cutting from TMT Re-bars by abrasives, grinded and polished one side is used for chemical composition testing in a spectrometer. The spectrometer takes 10 to 15 seconds to give results in printed form of a maximum of 26 elements in the TMT. The spectrometer mainly gives the results of the percentages of carbon, sulphur, and phosphorus which are important as per BIS. In case of micro alloyed grade TMT, percentages of chromium, copper, manganese etc. are also shown by the spectrometer.

The maximum allowable percentages of different elements as mentioned in the IS: 1786-2008 are as below:

| Elements | #Percent, Maximum | |||

| Fe 415/415D | Fe 500/500D | Fe 550/550D | Fe 600 | |

| Carbon | 0.30/ 0.25 | 0.30/0.025 | 0.300/.025 | 0.30 |

| Sulphur | 0.060/0.045 | 0.055/0.040 | 0.055/0.040 | 0.040 |

| Phosphorus | 0.060/0.045 | 0.055 /0.040 | 0.050/0.040 | 0.040 |

| Sulphur & Phosphorus | 0.110/0.085 | 0.105 /0.075 | 0.100/0.075 | 0.075 |

Basic Construction Safety Guidelines

Construction sites are always exposed to high risk. Because of the kind of work, materials, processes etc. It is important to ensure safety at work starting from the workers, engineers, employees and everyone else. Like the way it is important to use only Verified and Best Quality TMT Bars in the same way few factors are important to be taken care of while working at construction site:

- Wearing Safety Shoes is mandatory while present at construction site

- Wearing Construction Helmet is important while present at site

- Always carry dust protective mask and wear it whenever it is required

- Inspect all the equipments before using and ensure that it is secured

- To deploy an efficient supervisor is important to run all the work at construction site smoothly